Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

Investment casting uses the lost-wax method to make metal parts. First, you make a wax pattern. The wax pattern looks like the final part. You make a wax pattern for each part you need. Then, you cover the wax pattern with ceramic. The ceramic gets hard. You melt the wax and take it out. This makes a hollow shell. You pour hot metal into the shell. The metal cools and forms the part. Investment casting is very precise. It can make complex shapes. It does not create much waste.

Investment casting is also called lost wax casting. People have used it for over 5,000 years. It started in ancient Mesopotamia and Egypt. At first, people made jewelry and religious items. Now, many industries use this method. It is very useful.

Year | Market Size (USD) | CAGR (%) |

|---|---|---|

2024 | 106.54 billion | 4.7 |

2032 | 153.84 billion | N/A |

Investment casting uses the lost-wax method to make metal parts. These parts can have tricky shapes and little waste.

The process starts with a wax pattern. Then, a ceramic shell is made. Hot metal is poured into the shell. This makes the final part.

Investment casting has many good points. It gives smooth surfaces and close fits. It also saves energy. This makes it great for aerospace and car companies.

Think about investment casting for parts that need to be exact. But know it costs more and takes longer for small amounts.

Always talk to experts and pick the best materials. This helps you get the best results for your investment casting projects.

The first step is making a wax pattern. This pattern is the same size and shape as the final part. Melted wax goes into a metal mold. The wax cools and gets hard inside the mold. You take out the wax pattern carefully so it does not break. There are different waxes for different jobs. Some waxes make strong patterns with lots of detail.

Type of Wax | Function | Key Properties |

|---|---|---|

Runner Waxes / Gating Waxes | Make paths for the hot metal to flow | Very stable, shows details, strong when handled |

Soluble Waxes (Core Waxes) | Create tricky inside shapes | Melts easily, leaves little behind, low melting point |

Repair Waxes / Sealant Waxes | Fix small mistakes in patterns | Sticks well, does not shrink much, easy to use |

Adhesive Waxes (Sticky Waxes) | Stick patterns to the main runner | Sticks fast, holds tight |

Release Waxes / Parting Waxes | Stops sticking to the mold | Does not stick, leaves little behind |

These waxes help make sure the pattern is right for the next step.

You connect each wax pattern to a main wax stick called a sprue. The sprue is like a tree trunk. The patterns are like branches. You use heat or sticky wax to attach them. You check the tree to make sure it is straight and strong.

Get the wax sprue ready.

Attach the wax patterns with heat or sticky wax.

Look at the tree to find any problems.

Putting patterns on a tree lets you make many parts at once. This saves time and cuts down on waste. It also helps all the parts turn out the same.

You dip the wax tree into a wet ceramic mix. The mix covers the wax and makes a thin coat. You sprinkle sand or powder on the wet surface. You let it dry, then dip and sprinkle again. You do this many times. Each layer dries before the next one. The shell gets thick and strong.

Material Type | Characteristics |

|---|---|

Silica Sol Binder | Easy to use, stays stable, gives a smooth finish |

White Corundum Powder | Very pure, stands up to heat |

Mullite | Handles heat, makes the shell stronger |

Zircon Flour | Used first, makes a smooth shell |

Alumino-silicate Flour | Used later, makes the shell thicker |

Nano-based Colloidal Silica | Holds the shell together |

Zircon Sand | Used first as sand |

Molochite | Used later as sand |

These materials help the shell stand up to heat and pressure.

You put the ceramic-covered tree in a hot oven or autoclave. The heat melts the wax and it runs out. Now you have a hollow ceramic shell. This is called the "lost wax" step because the wax is gone. The shell has the same shape as the part you want.

Safety tip: Wear special clothes and eye protection. This step uses high heat and can make smoke.

You heat metal until it melts. You watch the temperature closely. Good control makes strong, accurate parts. Pour the melted metal into the hot shell. The metal fills every space inside. The metal cools and gets hard. It takes the shape of the wax pattern.

Keeping the right temperature helps make better parts. If the temperature is wrong, you can get cracks or holes.

You break the shell to get the metal parts out. Cut each part off the main sprue. Clean the parts to get rid of shell pieces or rough spots. You can grind, machine, blast, or polish the parts to make them smoother.

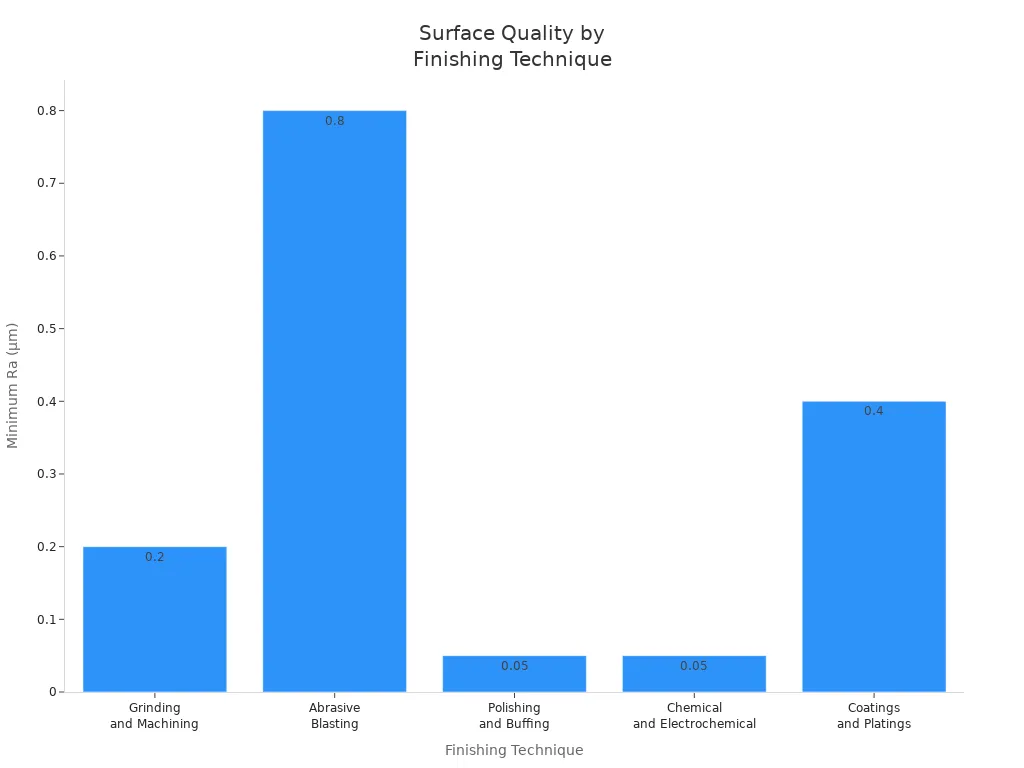

Finishing Technique | Surface Quality Impact |

|---|---|

Grinding and Machining | Makes parts very smooth; bad use can make rougher |

Abrasive Blasting | Glass beads: smooth; alumina: a bit rougher |

Polishing and Buffing | Can make a mirror-like shine |

Chemical and Electrochemical | Electropolishing: very smooth finish |

Coatings and Platings | Nickel plating: smooth surface |

You check each part to make sure it is good. You use tools like calipers and special machines. Sometimes you use X-rays or sound waves to look for hidden problems.

Investment casting makes exact and tricky parts. You can use it for many metals and shapes. The lost wax method helps you make parts with little waste and a great finish.

Investment casting makes very accurate parts. It can make shapes that are hard to do with other ways. You can get thin walls and sharp corners. The process also makes fine details. Many companies need these special shapes. Parts from investment casting fit together really well. Most of the time, you do not need to machine them more. You can count on this process to give you the right shape every time.

Tip: If you want parts with tricky shapes or tight fits, investment casting is a great choice.

Investment casting gives parts a smooth surface. There are not many rough spots. You do not need to polish much. The finish can be as smooth as RMS120. This is much better than sand casting. You also get tight tolerances, like +/-0.005 inches per inch. Your parts look nice and work well.

Process | Surface Finish (RMS) | Tolerance (inches) |

|---|---|---|

Investment Casting | RMS120 | +/-0.005 per inch |

Sand Casting | RMS560 | N/A |

You can get flat and round shapes that are very exact.

Holes as small as 1/2 inch can be very close in size.

You save time because you do not need draft angles or extra machining.

Investment casting uses less material and energy. You only use the metal you need for each part. The process makes parts close to the final shape. You do not waste much metal. You also save energy because there are fewer steps and less heat.

Environmental Benefit | Description |

|---|---|

Reduced Material Waste | You use less metal and make less scrap. |

Energy Efficiency | You use less energy for each part. |

Emissions Reduction | You help lower greenhouse gases. |

Recyclability and Reusability | You can recycle and use materials again. |

Avoidance of Hazardous Materials | You do not use toxic stuff in the process. |

Longevity and Durability | Your parts last longer and need fewer fixes. |

Integration and Simplified Assembly | You can join parts together, which saves material and helps the environment. |

Investment casting is a smart pick for many companies. You get tricky shapes, smooth surfaces, and very exact parts. You also help the planet by using less energy and making less waste.

Investment casting has many good points, but it also has limits. The process takes a long time and needs a lot of work. Skilled workers must do each step. This makes it cost more than some other ways to make parts.

Investment casting needs lots of work and time. It costs more because making wax patterns is expensive.

Making thin-walled parts can be hard. Sometimes, the metal does not fill every space. You might see problems like shrinkage, porosity, or cold shuts.

It is hard to make thin-walled parts with investment casting. The metal may not fill the mold. You can get shrinkage, porosity, or cold shuts because the metal cools too soon or travels too far.

You can also get rough spots or tiny holes inside the part. These problems happen when gas gets trapped or the mold is not made well.

Defect Type | Causes | Solutions |

|---|---|---|

Porosity | Gas gets trapped or metal shrinks as it cools | Make better vents in the mold, control the pouring heat, remove gas from the metal, use grain refiners, design the mold well |

Surface Defects | Bad mold material or rough handling | Use good mold materials, handle molds with care, make wax patterns well, build shells right, treat surfaces after casting, keep equipment in good shape |

Making only a few parts costs more. The setup and tools are pricey unless you make many parts.

Investment casting costs too much for small batches. Making special parts or prototypes takes weeks or even months.

You should pick another way if you need parts fast or want to save money. Investment casting takes longer than some other ways.

Investment casting has more steps, so it takes longer than other methods.

Long production times can be a problem if you need parts quickly.

If you only need a few parts, another method may be better. High tool costs and setup times make it hard for small jobs.

Special metals cost more.

Complicated parts need pricey molds.

Small batches cost more for each part.

Extra steps like machining add to the price.

If you need big or simple parts, try sand casting or machining. These ways can save time and money.

Investment casting costs more because workers must make wax patterns and ceramic shells by hand.

Always think about what you need before picking investment casting. Look at the cost, speed, size, and number of parts you want.

You can choose from many metals when you use investment casting. Each metal gives your part different strengths and features. Some metals work better for certain jobs. You might want a part that is strong, light, or can handle heat. Here is a table to help you see how common metals affect your final product:

Material Type | Influence on Final Product |

|---|---|

Stainless Steel | Offers high strength and corrosion resistance. |

Aluminum | Lightweight and good thermal conductivity. |

Special Alloys | Tailored properties for specific applications. |

Stainless steel works well if you need parts that last a long time or face water and chemicals. Aluminum helps when you want parts that do not weigh much. Special alloys let you get just the right mix of strength, heat resistance, or other features. You can pick the metal that fits your needs best.

You need more than just metal to make a good part. The pattern and mold materials play a big role in how your part turns out. You start by making a wax pattern. This pattern shapes your part. You use a metal die to form the wax. The wax must be strong enough to hold its shape but soft enough to remove from the die.

After you make the wax pattern, you build a ceramic mold around it. The ceramic must handle high heat and keep its shape. If you use the right materials, your mold will not crack or break. This helps your part come out smooth and detailed.

Here are the main steps where pattern and mold materials matter most:

Metal die construction

Wax pattern production

Ceramic mold creation

Pouring and solidification

Shakeout and cleanup

Tip: If you pick the right pattern and mold materials, you get better parts and fewer problems.

The choice of these materials affects the look, strength, and detail of your finished part. You can make parts for cars, planes, or even medical tools. Investment casting gives you many options for both metals and molds.

Investment casting is used for many airplane parts. It helps make parts that are safe and work well. Some examples are:

Turbine blades and vanes in jet engines. These must handle a lot of heat and pressure.

Engine mounts and landing gear. These need to be strong but not heavy.

Fasteners and control surfaces. These must work in hard conditions.

These parts need to be strong and exact. They also must handle very hot temperatures. Investment casting helps meet these needs every time.

Many car parts are made with investment casting. This method makes parts lighter and stronger. It also allows for more complex shapes. Here is a table that shows some examples:

Component Type | Examples |

|---|---|

Engine components | Cylinder heads, intake manifolds, camshafts |

Transmission components | Gear housings, gears, shafts |

Suspension components | Control arms, knuckles, steering components |

Brake components | Calipers, rotors, brackets |

Other components | Fuel injectors, turbochargers, trim |

Lighter parts help cars use less fuel. Exact shapes help cars run better and last longer. Complex parts mean fewer pieces and easier building.

Investment casting is used for many medical tools and devices. It helps make parts that are safe, strong, and exact. Some common uses are:

Surgical tools like forceps and scalpels. These must be very accurate and safe.

Hip and knee implants. These must fit the body and last a long time.

Dental crowns and bridges. These need to fit well and work right.

Parts for machines that help doctors find problems.

All these parts must follow strict safety rules to protect patients.

Investment casting is used in many other jobs. It helps make detailed and reliable parts for special needs. Some examples are:

Food and dairy machines like meat slicers and coffee makers.

Gun parts such as triggers and receivers.

Boat hardware like pumps and fittings.

Military items such as bomb racks and missile parts.

Power plant parts like valves and clamps.

This process works for many different industries and needs.

Investment casting lets you create detailed metal parts using a lost-wax process. You get strong, precise shapes and smooth surfaces. It works best for small batches and complex designs. You may face higher costs and longer production times.

Key factors to consider:

Cost for small runs

Quantity of parts needed

Surface finish and detail

Speed of production

Shape and size limits

Strength requirements

Expert tips for success:

Start simple to lower risks.

Keep wall thickness consistent.

Choose suppliers who offer design help and strict quality checks.

If you need high-precision or complex parts, investment casting may be the right choice. Talk to experts before starting your project.

You can use stainless steel, aluminum, and special alloys. Each metal gives your part different strength and features.

Metal | Main Benefit |

|---|---|

Stainless Steel | Strong, resists rust |

Aluminum | Light, conducts heat |

Alloys | Custom properties |

Investment casting gives you smoother surfaces and tighter tolerances. Sand casting works better for large, simple parts.

Tip: Choose investment casting for detailed shapes. Pick sand casting for big, basic parts.

You can make small to medium parts best. Large parts may cost more and take longer.

Small parts: Best results

Medium parts: Good results

Large parts: Higher cost, longer time

You can use investment casting for medical tools and implants. It meets strict safety rules.

Doctors trust it for strong, clean, and exact parts.

You can use calipers, X-rays, and sound waves. These tools help you find hidden problems.

Calipers: Measure size

X-rays: See inside

Sound waves: Find cracks