Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

Investment casting materials affect how your product works, lasts, and costs. You should think about the kind of alloy and what it can do. Each alloy has its own strong points. For example:

Stainless steel is tough and good for car parts.

Cast iron is exact and does not cost much.

Copper alloys do not rust in pipes and wires.

Super alloys can take heat and wear in planes.

Dongying Yicheng Precision Metal Co., Ltd has many of these materials. The company uses new methods and a smart team. They help you pick the best material for your needs.

Investment casting materials affect how products work, last, and cost. Pick carefully so your project does well.

Stainless steel is used a lot in many fields. It is strong and does not rust easily. It works well for food tools, medical items, and car parts.

Look at what each alloy can do. Aluminum alloys are light and good for small parts. Nickel-based alloys work best in places with lots of heat.

Think about what your project needs before you pick materials. Things like money, strength, and weather matter a lot.

Talk to experts to help you choose. They know a lot and can help you avoid mistakes. This helps you pick the right material for your job.

Dongying Yicheng Precision Metal Co., Ltd has many investment casting materials. You can pick from stainless steel, duplex stainless steel, carbon steel, nickel-based alloys, bronze, aluminum alloys, copper alloys, super alloys, and cast iron. Each material is special in its own way. You can choose what fits your project best. The company makes turbo casting, food equipment casting, auto casting, polishing casting, pump casting, valve casting, impellers, and burner casting. You get good quality and help from experts.

Stainless steel is strong and does not rust easily. Many industries use it. It is found in food processing, medical tools, car parts, and chemical equipment. There are different grades to pick from. Each grade works best in certain places.

Grades | Features | Applications |

|---|---|---|

304 | Austenitic, food grade, good for less corrosive air | Medical, food, chemical, mechanical, pipe, automotive |

316 | Higher nickel, better corrosion resistance, marine use | Fire fighting, auto, marine, chemical, pipeline, construction, food |

410 & 416 | Martensitic, high strength, heat treatable, lower corrosion resistance | Auto parts, tools, knives |

17-4 PH | Martensitic, highest strength, good corrosion resistance | Military, medical, mechanical, turbines |

Stainless steel lasts a long time and needs little care. It can take heat and does not wear out fast. You see it in pumps, valves, impellers, and burner equipment. Dongying Yicheng has many certificates like ISO 9001, IATF 16949, Lloyd's Register, CCS, TUV/PED/AD W2000, ISO 14001, and ISO 45001. You always get good quality.

Certification/Standard | Description |

|---|---|

ISO 9001 | Quality management certificate |

IATF 16949 | Automotive quality management standard |

Lloyd's Register | Marine Society Approval |

CCS | Marine Society Approval |

TUV/PED/AD W2000 | EU pressure vessel certification |

ISO 14001 | Environmental management standard |

ISO 45001 | Occupational health and safety management standard |

Carbon steel is strong and can be used in many ways. You find it in military vehicles, oil and gas tools, and machines that move things. It is also used in farming, guns, cars, oil work, food, dairy, meat, waste, logging, utilities, power, building, machine tools, mining, pumps, valves, and medical tools.

Element | Function | Impact |

|---|---|---|

Carbon (C) | Increases hardness and strength | Essential for strength and heat treatment |

Silicon (Si) | Enhances casting properties | Improves fluidity, reduces defects |

Manganese(Mn) | Increases hardenability and weldability | Allows deeper hardening |

Phosphorus(P) | Kept low to prevent brittleness | Maintains toughness |

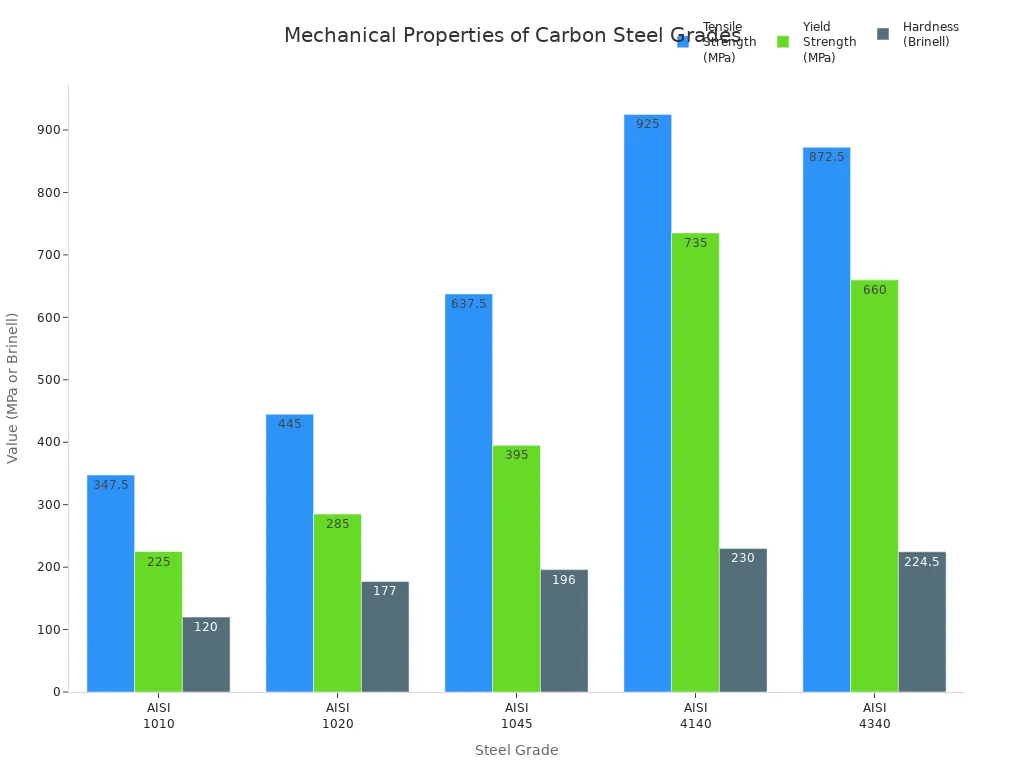

Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) |

|---|---|---|---|

AISI 1010 | 330 - 365 | 205 - 245 | 105 - 135 |

AISI 1020 | 420 - 470 | 250 - 320 | 119 - 235 |

AISI 1045 | 565 - 710 | 310 - 480 | 163 - 229 |

AISI 4140 | 850 - 1000 | 620 - 850 | 190 - 270 |

AISI 4340 | 745 - 1000 | 470 - 850 | 201 - 248 |

Aluminum alloys help make light and detailed parts. You get smooth surfaces and exact shapes. They are used in planes, cars, and electronics. You save material and make less waste. You can change the alloy to fit your needs.

Tip: Aluminum alloys give even strength and a nice finish. Big parts may be hard to make.

Copper alloys move heat and electricity very well. They are used in ships and factories. They do not rust as fast as other materials. You see copper alloys in pipes, wires, and electric parts.

Nickel-based alloys are strong in high heat and do not rust. You use them in planes, cars, energy, chemical plants, and oil and gas.

Application Area | Performance Benefits |

|---|---|

Aerospace | Turbine blades, engine components, aircraft structural parts |

Automotive | Exhaust manifolds, turbocharger components, fuel system parts |

Energy | Gas turbine components, nuclear reactor parts, heat exchangers |

Chemical Processing | Pump and valve components, reactor vessels, piping systems |

Oil and Gas | Downhole tools, valve bodies, offshore platform components |

You get great rust protection, strength in heat, and good mechanical properties. You can make detailed shapes for tough jobs.

Bronze is strong, easy to shape, and does not rust fast. You use it for bearings, ship parts, valve parts, propeller hubs, rudder fittings, bearing housings, transmission parts, pump impellers, valve bodies, bushings, brackets, fancy hardware, electronic cases, and plumbing parts.

LG2 Bronze Casting: Good for bearings and parts that wear.

Gunmetal Casting: Does not rust in ships.

Marine Bronze Castings: Used for propeller hubs and rudder fittings.

Automotive Bronze Components: Bearing housings and transmission parts.

Industrial Machinery Parts: Pump impellers and valve bodies.

Aerospace Bronze Castings: Bushings and brackets.

Architectural Bronze Hardware: Fancy decorations.

Electronic Component Housings: Blocks electromagnetic waves.

Plumbing and HVAC Bronze Fittings: Valve parts and manifolds.

Duplex stainless steel is about twice as strong as regular stainless steel. It does not rust or pit easily. It works well in tough places like chemical plants and on ships.

Duplex stainless steels are great at stopping rust.

They are best where pitting and stress rust are problems.

Material Type | Strength Comparison |

|---|---|

Duplex Stainless Steel | About twice as strong as standard stainless steel |

Standard Stainless Steel | Baseline strength |

Super alloys help make parts that work in very hard places. You use them in planes, energy, and chemical plants. You get exact shapes and smooth surfaces.

Superalloy | Unique Properties |

|---|---|

Inconel 718 | Withstands temperatures up to 700°C and maintains tensile strength exceeding 1,000 MPa. |

Hastelloy X | Outstanding oxidation resistance at temperatures up to 1,200°C. |

Rene 80 | Enhanced creep resistance due to tantalum and titanium. |

The process makes parts close to the final shape.

You get exact sizes and smooth surfaces.

Wax or resin patterns and strong ceramic molds are used.

Investment casting gives you parts with smooth surfaces. These parts last a long time in tough places.

Cast iron is tough, easy to shape, and stops vibration. You use it for machines, car parts, and building equipment.

Cast iron is known for being tough and easy to shape.

It helps stop vibration in machines.

You can pick the best investment casting material for your project by learning about these choices. Dongying Yicheng Precision Metal Co., Ltd helps you find the right material, so you get good quality and can trust your parts.

You want parts that last and stay strong. Different alloys have their own strength and durability. Here is a table to help you compare:

Alloy Type | Strength Characteristics | Durability Characteristics |

|---|---|---|

Stainless Steel | High strength, excellent corrosion resistance | Good thermal stability, great for structures |

Titanium Alloys | High strength-to-weight ratio, resists corrosion | Best for light parts in tough places |

Superalloys (Inconel) | Very high mechanical strength, thermal stability | Keeps properties in extreme environments |

Aluminum Alloys | Moderate strength, lightweight | Needs coatings for better durability |

Magnesium Alloys | Good strength, lightweight | Moderate corrosion resistance, good for weight cuts |

You see these alloys in pumps and valves. They are also used in car parts. These alloys help equipment work longer and safer.

Corrosion can hurt parts fast, especially in water or chemicals. Some investment casting alloys resist rust and corrosion. Stainless steel, copper-based alloys, and nickel-based alloys are good choices. Here is a quick look:

Material | Corrosion Resistance Description |

|---|---|

Copper-based alloys | Excellent, works well in harsh places, has antimicrobial properties |

Stainless steel | Resists rust, good for wet or chemical areas, keeps properties over time |

Nickel-based alloys | Strong and durable, handles high stress, keeps strength at high temperatures |

Cobalt-based alloys | High strength, tough, great corrosion and wear resistance, reliable in tough conditions |

Aluminum alloys | Light, strong, resists corrosion, good for harsh environments |

You find these materials in oil and gas jobs. They are also used in water treatment and marine industries.

Some jobs need parts that can take heat. Nickel-based superalloys and Cr–Si alloys work well at high temperatures.

Alloy Type | Maximum Operating Temperature | Liquidus Temperature |

|---|---|---|

Nickel-based superalloys | 1100 °C | 1455 °C |

Cr–Si alloys | Above 1900 °C | Up to 1900 °C |

Refractory metal alloys | Above nickel-based alloys' max | N/A |

You use these alloys in burner equipment and turbines. They are also used in engines.

Tip: Heat-resistant castings work best above 1,200ºF (670ºC). They keep their shape and strength even in hot gas or under heavy loads.

Investment casting lets you make complex shapes with less weight. You can cut part weight by up to 80% compared to old ways. This helps cars and planes use less fuel. You also save material and labor. The process gives smooth, detailed parts that need less finishing.

The alloy you pick changes your budget. Here is a table to compare costs:

Casting Method | Initial Costs | Material Costs | Reusability | Overall Cost Impact |

|---|---|---|---|---|

Investment Casting | Higher | More expensive alloys | Single-use | Higher project budgets |

Sand Casting | Lower | Less costly materials | Reusable | More economical for repeats |

Investment casting uses high-performance alloys, which can cost more.

Sand casting uses cheaper materials, so it fits simple designs.

Your material choice shapes your project budget, especially for tough jobs.

Pumps and valves need parts that are strong. They must also be reliable. Many makers use the same alloys for both. Stainless steels like CF8M and CF3M are common. These alloys do not rust and last a long time. Duplex and super duplex steels are even stronger. They also resist chemicals well. Nickel-based alloys work in hot jobs.

Stainless steels: Good at stopping rust

Duplex and super duplex steels: Strong and resist chemicals

Nickel-based alloys: Work in high heat

Pick materials that fit your needs. You want parts that do not rust. They should be strong and exact. Dongying Yicheng has many metals for these uses.

Impellers and burner equipment work in tough places. They need materials that can take heat and wear. Carbon steels are used a lot. Low-carbon steels bend easily and can be welded. Medium-carbon steels are strong and tough. High-carbon steels are very strong and do not wear out fast.

Carbon Steel Grade | Carbon Content | Key Properties | Applications |

|---|---|---|---|

Low-Carbon Steels | < 0.25 %C | Bendable, weldable, strength 400–550 MPa | Valve bodies, flanges, fittings |

Medium-Carbon Steels | 0.25–0.60 %C | Strong, tough, strength 500–650 MPa | Pump housings, brackets |

High-Carbon Steels | > 0.60 %C | Very strong, resists wear, >900 MPa | Cutting tools, wear plates |

Choose the steel grade that fits the job. If you need parts for heat or wear, use high-carbon or nickel-based alloys.

Cars and ships need parts that last. They must also be safe. Stainless steel is strong and does not rust. Superalloys work in hot places. Carbon steel is used for many things. Nickel-based alloys are good for important spots. Cobalt-based alloys are extra strong.

Material Type | Properties |

|---|---|

Stainless Steel | Strong, does not rust |

Superalloys | Good in high heat |

Carbon Steel | Used for many jobs |

Nickel-based Alloys | Great for key parts |

Cobalt-based Alloys | Very strong and tough |

Check if the part is exact, does not rust, and can take heat. Dongying Yicheng follows strict rules for these jobs.

Food and medicine need clean and safe metals. You must use alloys that follow FDA and cGMP rules. Stainless steel is a top pick. It does not rust and is easy to clean.

Tip: Make sure your metal meets FDA and ISO 13485 rules for safety.

Regulatory Framework | Description |

|---|---|

FDA Guidelines | Makes sure medical devices are safe and good |

ISO 13485 | Checks quality for medical devices |

cGMP | Good ways to make safe products |

Pick metals that are approved for food and medicine. Dongying Yicheng helps you find the right alloy for your project.

To get the best results, first look at what your project needs. Use this checklist to help you decide:

Check how much money you can spend. The price of materials and how things are made can change your costs.

Think about what the part must do. Look at how strong it needs to be, if it needs to fight rust, or if it must handle heat.

Try out different materials. Do small tests to see how each investment metal alloy casting works.

Pick a manufacturer you can trust. Choose one with a good name and strong quality checks.

Tip: Only use special alloys if your project really needs them. Using too fancy materials can make things cost more for no good reason.

Here is a table to help you compare important things:

Factor | Why It Matters |

|---|---|

Cost | Helps you stay on budget |

Material Properties | Makes sure the part works right |

Testing | Shows if the material is a good fit |

Manufacturer Reputation | Helps you feel confident |

You can avoid problems by checking how metals act when hot or cold. Some metals change shape with heat or cold. Also, think about what happens after casting. Some precision casting metals are easier to cut or weld than others.

You do not have to choose alone. Work with people who know about investment metal alloy casting. They can help you pick the best material for your project. Here are steps you can follow:

Write down what your part needs to do. List the most important things.

Set your budget. Know how much you can spend.

Decide how many parts you need. If you need a lot, you might need a different alloy.

Talk to experts about materials. They know the newest choices for precision investment casting.

Look up your options. See how each investment metal alloy casting works for your job.

You can make better choices if you ask questions and listen to experts. This way, you get the right material and do not waste money.

Picking the right investment casting material helps your product last longer. It also makes your product work better. Mechanical strength and corrosion resistance make parts stronger. These features help parts last longer. The investment casting process lets you make exact shapes. You get smooth surfaces with fewer mistakes. Quality control checks, like non-destructive testing, make sure every part is good.

Feature | Benefit |

|---|---|

Mechanical strength | Reliability |

Corrosion resistance | Longer lifespan |

Precision casting | Fewer defects |

Quality control | Consistent quality |

Dongying Yicheng has many certificates. These include ISO 9001, IATF 16949, Lloyd's Register, CCS, TUV/PED/AD W2000, ISO 14001, and ISO 45001. You get good parts from a strong company. When you pick materials, think about the design, how smooth the surface is, and how many parts you need. Always ask experts for advice. This helps you get the best quality for your project.

Stainless steel, carbon steel, aluminum alloys, copper alloys, bronze, nickel-based alloys, and cast iron are used a lot. These metals are strong and last a long time. They also do not rust easily. You can use them for pumps, valves, car parts, and food machines.

Precision helps make shapes that are exact and smooth. It makes sure the metal fits your design well. You get fewer mistakes and better working parts. Precision casting lets you make hard shapes from metals like stainless steel and nickel alloys.

You need to pick metals that fit your project. Some metals stop rust. Others can take heat or pressure. You get better results when you use the right metal for pumps, valves, ships, or medicine. Precision casting helps you use the best metal for each job.

You can use precision casting for many metals. Stainless steel, carbon steel, bronze, and nickel-based alloys work well. Some metals need special care to cast. You should ask experts if your metal is good for precision casting.

You get strong metals and help from experts. The company uses new precision methods. It has many metals for different jobs. There are strict checks and certificates. You can trust the metals and how well each part is made.

Tip: Always ask about the metals and precision rules before you start your project.

content is empty!